1. 滑块干涉的倒钩请加胶填平至滑块可以平顺滑动

The undercut area where interface with slide block need to be filled material to help the slide can move smoothly.

2. 加胶太多

The thickening added too thick.

3. 加胶面积太大

The thickening area is too wide.

4. 灌点位置需要移动。

Gate position need to move.

5. 拆滑块的位置

The split line of slide block / The area of slide.

6. 此处有尖角,填充比较困难。

This area is hard to be filled due to the

sharp feature.

7. 此处钢材太薄,强度不足够而且不容易冷却。

The strength of this area is too weak and is not easy to get cold due to the steel too thin.

8. 这个面是装配面,不能加胶。

This is critical surface where is not allow to add material.

9. 此处胶位太厚,会有缩水,建议减小塑料厚度以改善。

This thick wall area

might because sink mark, please reduce some wall thickness to improve

it.

10. 此处做滑块会有结合线,请确认是否可以接受?

Please confirm whether it is acceptable to has slide split

line if we have slide in this area.

11. 请确认此面是不是外观面。

Please confirm whether it is critical

surface or not?

12. 此处有倒扣,能否减胶,使公母模靠破,不做滑块和斜销。

Please /confirm/i

whether we can reduce material to the area where have undercut as indicated to have shut off on core and cavity

side. No slide block and lifter to be made.

13. 请尽快确认问题点,否则会影响交期。

Please confirm these questions asap. Otherwise the lead-time will be extended.

14. 加大拔模角,以便脱模顺利

We would suggest to enlarging draft to help tool released.

15. P.L 面开在此处,模具上会有尖角和刀口,对模具寿命有影响

There are sharp edges if set the parting line at here ,

It will reduce the tool life.

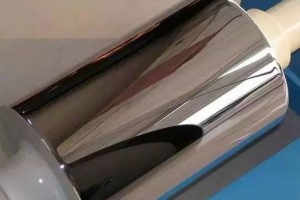

16. 请问此产品的面是否为外观面?表面做什么处理?是蚀纹还是抛光?

Can you tell me whether the surface of this part is a visible/ esthetic one? What will we do for its surface? Texture or polishing?

17. 请问产品这个面可以加顶针或顶块吗?产品允许加扁顶针吗?

Does this part need an ejector pin or an ejector bar? Can we add an ejector blade?

18. 这个产品的柱位我们打算做司筒或镶针,可以吗?

Can we add ejector sleeves or ejector pins in the boss

of this part?

19. 这个位置有倒扣不能脱模,我们打算做滑块,在此面上会有分模线,可以接 受吗?

There is an undercut

at this position and it need a slider. It will also have a parting line on this side, is that OK?

20. 我们打算在这个位置做斜顶或内侧滑块,有问题吗?

We will make the lifter or inner slider in this position, will that be a problem?

21. 你们提供的 2D 产品图与 3D 产品图不一致,请问哪一个图是正确的? The 2D and 3D drawing you provided is not the same, can you tell me which one is

correct?

22. 按照你们提供的缩水率千分之五,这个模具的尺寸已经做到了模具图面要 求。

According to the shrinkage one over two hundred, the mold has been done in the right dimension.

23. 产品的这个位置太小,导致模具钢料太薄,能够加宽这个位置吗?

This position is too small and will make the steel material here too thin, can we widen it here ?

24. 斜顶与后面的 Boss 空间太小,斜顶在运动时会干涉到柱子,能移动这个柱子 的位置吗?

The angular lifter interferes with the boss during ejection. Please consider changing the position of the boss.

25. 这个筋条太薄,而且高度比较高,注塑时很难填充,可以增加这个筋条的厚 度吗?

The rib here is too thin and on the high side, so it will be difficult to fill here when we do

the injection, can you increase the thickness of this rib?

26. 你是想将此筋条的高度加高/减低吗?假如加胶,我们将用放电方式加深。 Will you increase/decrease the material on this rib? If add the material, we will modify

it with EDM process.

27. 减胶修改的两种做法:

1. 做镶件;

2. 烧焊:因为镶件的底部有水路,我们简单的做法是烧焊处理,你们可以 接受吗?

There are two option if decrease the material:

Please note the red highlights because those areas have problems.

- 模具设计中设计用语解答

0评论2019-08-07

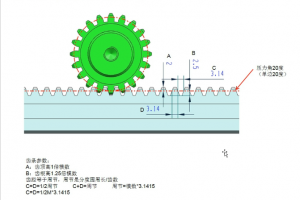

- 齿条与齿轮配合关系以及齿条的设计

0评论2019-08-06

- 双色模具经验总结

0评论2019-08-06

- 热锻模具用什么材料,热锻模具的热处理方法

0评论2019-07-15

- 塑胶模具使用热流道的好处

0评论2019-07-15

行位、斜顶、运水、疏气坑、唧咀.....别说你不懂!

一、模胚1、客户模号打在非基准面上,字体端正整齐。2、按要求在方铁上雕上客户编号。3、ab板之间四角要做撬模角,大模40x45度;深10mm(两边计),小模25x45度;深 6mm(两边计)。4、码模坑:高(25-35)x

0评论2019-07-15492

- 模具设计中的擦和碰面

0评论2019-07-15

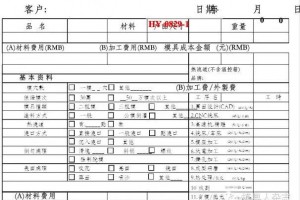

- 模具报价快速计算法(不懂就转)

0评论2019-07-15

- 纯干货丨模具干了一辈子:表面粗糙度为什么用0.8, 1.6, 3.2?

0评论2019-07-15

注塑模具八大类,一定要牢记!

注塑模具的分类(1) 单分型面注塑模开模时,动模和定模分开,从而取出塑件,称单分型面模具,又称双板式模。它是注塑模具中最简单最基本的一种形式,它根据需要可以设计成单型腔注塑模,也可以设计成多型腔注塑模,是

0评论2019-07-13323